Tensionning

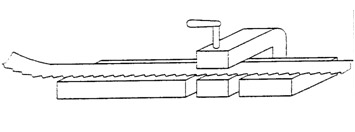

This task consist in lengthening some parts of the blade on all its lenght thanks to a machine called a saw stretcher or a streching machine.

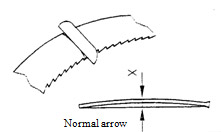

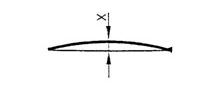

The tensionning gives to the blade a certain shape called « curved » that allows the blade to take the exact shape of the pulleys and to make the sides when the blade is tensionned between the pulleys. This avoids deviations of the blade in the wood.

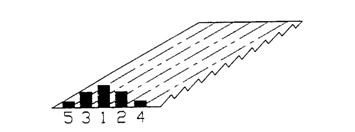

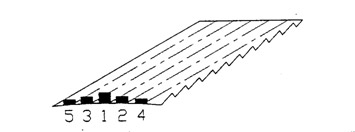

| CONTROL | PRACTICE (CURVED IN THE MIDDLE) |

|

|

New Blade |

|

Lack of tension |

|

Too much tension |

|

There are four shapes of pulleys :

- curved in the middle (particularly for double cut blades)

- curved in 2/5th

- flat pulley (only for big structures)

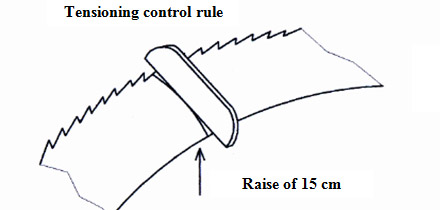

Tensionning control is done thanks to a filament flat rule that had the same with as the blade.

Convex position - Outside of the curve

Concave position - Inside of the curve

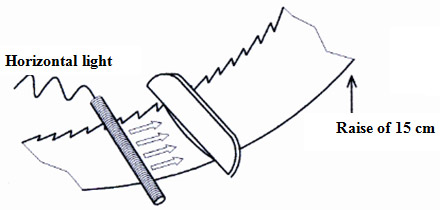

As the blade is raised by about 15 cm in the convex and concave position but it is positionned at 50-60 cm of the control point for the latter.

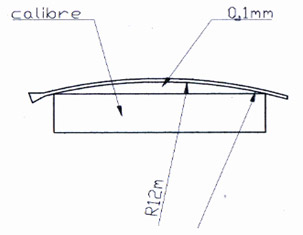

N.B : For double cut blades and those in large dimensions, using a tensionning model with a radius of 12 m using an horizontal light at the back of the model this in concave position.

A uniform light of 0.1 mm should be seen on all the width of blade.

If the model touch some parts of the blade, it will be necessary to lenghten again those parts precisely that are gutters.

During the tensionning, it is important not to tense the blade too much because it damages the planishing and craks risk to appear in the gullet bottom and the blade will pull to the machine (weak pulling). A lack of tension will make the blade pull to the wagon (strong pulling).