Levelling

It consists in obtaining a perfect flatness when the blade is in a flat position i.e. in the sawing part in order to avoid deviations.

A better control is effectuated on a blade that is tensed between the pulley and in the part situated between the guides.

A blades with a bump outside will have a strong pulling i.e.the product will be thinest at the end of the sawing operation.

When a bump is detected on a benching table, it is suppressed thanks to :

- A smithing hammer called British hammer

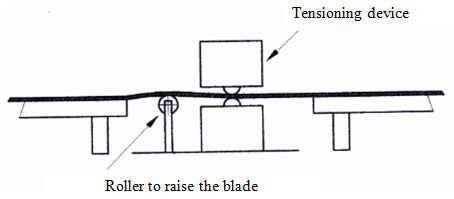

- A tension device if the bump is on a large lenght.

For this, the blade needs to be raised before or after the tension device.

The blade will be raised more or less high and the pression of the roller will be more or less strong according to the following scenarios :

1. If the bump is significant and the tension is correct : the blade is raised highly and the pressure is slight.

2. The bump is significant and there is a lack of tension : the blade is raised less high and the pressure is stronger.

3. The bump is weak and there is a lack of tension : the blade is raised slightly and the pressure is strong.

It is better to suppress the maximum defects with the tension device which leaves less trail than a hammer. Some tension devices have extensible rollers that allow to suppress the major levelling defects but it is necessary to press slightly as the roller can shear steel.

There is also automatic planishing machines, but it is necessary to check manually to suppress small defects, to level the part situated near the gullet bottom and to chek teeth after teeth if they are not bent.